Adaptive Optics Overview

Adaptive optics (AO) systems measure optical wavefront aberrations in real time and compensate for these using a deformable mirror. By correcting the wavefront aberrations, the optical system resolution is greatly improved.

Adaptive optics technology was initially developed for military use to compensate for atmospheric aberrations. Astronomers have used these same techniques to dramatically improve the resolution of ground-based telescopes. Over the past decade, new types of microelectromechanical systems (MEMS) based deformable mirrors (DM) have been developed that have dramatically reduced costs and size to the point that make AO technology useful for many more applications. Retinal imaging and biological microscopy are two examples. Others include aberration correction in laser systems to improve beam quality, laser pulse shaping, beam profile shaping.

Anywhere there are optical aberrations that need to be removed or an optical wavefront that needs to be controlled, adaptive optics concepts apply. The concept is very simple as the following figure demonstrates.

Anywhere there are optical aberrations that need to be removed or an optical wavefront that needs to be controlled, adaptive optics concepts apply. The concept is very simple as the following figure demonstrates.

An incoming wavefront is distorted because of optical path differences across the beam. These can come from some aberrating medium between the optical system and the object it is imaging or from aberrations in the optics themselves. A deformable mirror (DM) corrects the aberrated wavefront by compensating for optical path differences

This animated figure shows a typical adaptive-optics imaging system The three critical parts to an AO system are the DM that corrects the aberrations, the wavefront sensor that the measures the wavefront aberrations, and the AO control computer that orchestrates the real time correction. In an adaptive optics system, at every sample, the AO control computer calculates the wavefront errors that reflect off of the deformable mirror by subtracting the measured wavefront from a reference wavefront. It then corrects these errors by making adjustments to the shape of the deformable mirror. The sample and correct process is in real time in order to correct for time-varying aberrations. For biological applications, update rates are in the tens of Hertz. For astronomy and military applications, sample rates can be in the kilohertz to tens of kilohertz.

This animated figure shows a typical adaptive-optics imaging system The three critical parts to an AO system are the DM that corrects the aberrations, the wavefront sensor that the measures the wavefront aberrations, and the AO control computer that orchestrates the real time correction. In an adaptive optics system, at every sample, the AO control computer calculates the wavefront errors that reflect off of the deformable mirror by subtracting the measured wavefront from a reference wavefront. It then corrects these errors by making adjustments to the shape of the deformable mirror. The sample and correct process is in real time in order to correct for time-varying aberrations. For biological applications, update rates are in the tens of Hertz. For astronomy and military applications, sample rates can be in the kilohertz to tens of kilohertz.

Iris AO MEMS Deformable Mirror (DM) Technology

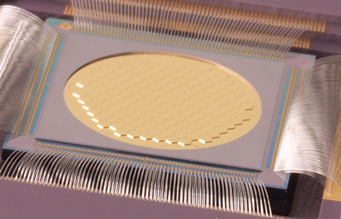

Iris AO has developed patented MEMS technology to manufacture deformable mirrors. These deformable mirrors range from 100 to 500 actuators with inscribed apertures from 3.5 mm to 7.7. The figure to the right shows our PTT489 deformable mirror line, which consists of 489 actuators. Because of their small size, the MEMS deformable mirrors are perfect for use in research, industrial, and commercial systems.

Iris AO has developed patented MEMS technology to manufacture deformable mirrors. These deformable mirrors range from 100 to 500 actuators with inscribed apertures from 3.5 mm to 7.7. The figure to the right shows our PTT489 deformable mirror line, which consists of 489 actuators. Because of their small size, the MEMS deformable mirrors are perfect for use in research, industrial, and commercial systems.

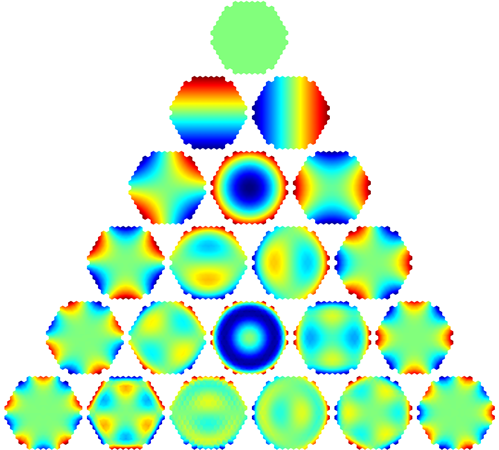

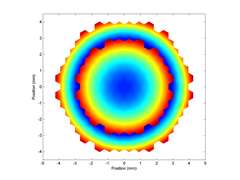

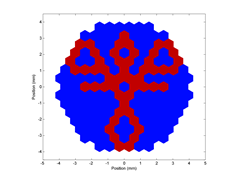

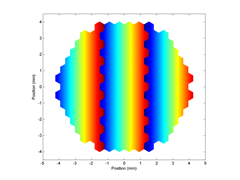

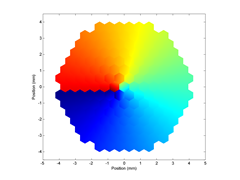

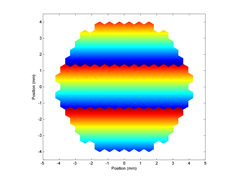

The Iris AO deformable mirrors consist of an array of tightly packed mirror segments that can be individually controlled in three degrees of freedom that are commonly referred to as piston, tip, and tilt. Examples of how you can position an array are in the figure below. Here we show the commonly known Zernike modal basis set as an example of smooth mirror shapes.

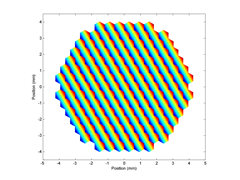

In addition to the smooth mirror shapes, the DM can create shapes with phase jumps such as phased arrays, Fresnel reflectors, and even optical vortices. For the case of optical vortices, researchers have shown that the optical vortices created by the PTT111 DM (111 actuators, 37 PTT segments) have better mode purity than the phase plates typically used to create them. [REFERENCE Tyson mode purity] Because the DMs are active devices, any vortex charge within the stroke capabilities of the DM can be written to the DM in real time.

The segmented technology has many advantages over so called continuous deformable mirrors. The calibrations for these DMs are more accurate than any others described in the research literature. Unlike most DM manufacturers, Iris AO calibrates all of its deformable mirrors. (Iris AO was the first manufacturer to offer fully calibrated DM systems.) With the calibrations, the DMs can be positioned using intuitive position commands (piston/tip/tilt) or Zernike coefficients.

Because the quality of the individual segments is so good, the gaps between the segments are small, and the calibrations are so accurate, researchers have been able to show that the Iris AO PTT111 deformable mirror (111 actuators, 37 PTT segments) performs on par with other continuous mirrors [REF Roorda paper]. The segment quality is so good that NASA researchers are using Iris AO DMs to develop space-based telescope instruments that will eventually be able to detect the faintest of planets orbiting close to stars. [REFERENCE RICK LYON PAPERS 2012], [REFERENCE RICK LYON PAPERS 2010]. Thus, the Iris AO segmented DMs can be used in all of the applications continuous deformable mirrors are used and for applications that require segmented devices as well.

A key advantage of the Iris AO technology is that it is robust to large temperature variations and various optical coatings. An active area of development is with dielectric coated DMs. Initial testing has shown that the deformable mirrors are capable of 300 W/cm2 average power handling without heat sinking. Analysis shows that with heat sinking and slightly improved coatings, the DMs will be able to handle 3 kW/cm2 of average power. Other tests have demonstrated peak power handling in excess of 1.7 GW/cm2 for pulsed applications. These results have been so promising, that Iris AO has won a Phase II SBIR from the National Science Foundation to further develop DMs for research and industrial laser applications.

The applications for deformable mirrors are growing steadily. Iris AO is actively developing DMs to meet the needs of new applications. Contact Iris AO to discuss applications and custom DMs.

The Role Of Iris AO In Research

Since its inception in 2002, Iris AO has been involved in the foremost industry research and experimentation in adaptive optics. Through collaboration with top researchers and organizations in fields such as biomedical imaging, astronomy, optometry, beam shaping, and portable laser communications, our products and scientists have been featured in over 50 research publications and conferences in December 2014. We are proud of your work! In an effort to provide a more detailed account of our product capabilities and potential, we have assembled these publications in an online database accessible to all: Iris AO Mendeley. If you have other publications featuring Iris AO products, please let us know.